Our Quality Process

Transparent operational workflow, step by step.

Selection

Defining grade & finish based on project needs.

Inspection

Factory-level QC with real-time visual reports.

Packaging

Foam-padded, weatherproof wrapped.

Delivery

Loading supervision & full export documentation.

Selection & Customization

We match your project needs with the perfect output, defining grade and finish before production.

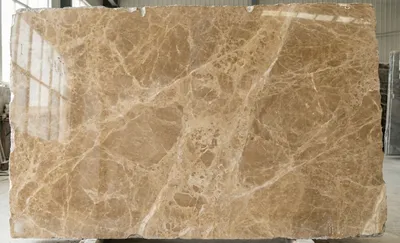

- ✓ Grade Selection: Premium, Standard or Commercial.

- ✓ Surface Finish: Polished, Honed, Brushed or Tumbled.

- ✓ Edge Detailing: Beveled, Straight or Bullnose check.

Quality Control

We act as your eyes on the factory floor. Detailed checks and visual proof before packing.

- ✓ Visual Report: High-res photos & videos of your order.

- ✓ Quality Check: Inspection for cracks, holes, or defects.

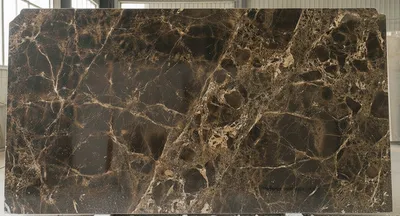

- ✓ Color Consistency Control: Ensuring uniform tone balance.

Safety Packaging

Robust protection for ocean transit. Wooden crates reinforced with internal foam cushioning.

- ✓ Heat-Treated Crates: Export-grade wooden protection.

- ✓ Shock Absorption: Full foam cushioning & separation.

- ✓ Weatherproofing: Nylon wrapping & strapping.

Logistics & Docs

Logistic transparency is priority. We manage loading with photo proof and provide full documentation.

- ✓ Loading Supervision: Secure lashing & photo report.

- ✓ Flexible Terms: Ready for FOB, CIF, or EXW.

- ✓ Full Documentation: Invoice, Packing List, BL & Origin Cert.

Why Us?

Zero Tolerance

Strict inspection on dimensions, corners, and surface finish. We reject what isn't perfect.

Transparent Process

You see what we see. Detailed photo & video reports of your order before shipment.

Single Point of Contact

From quarry to customs, deal with expert guidance. No miscommunication, no delays.